Monday, December 22, 2014

Carbon Drive Red

Bike style is getting a jolt of color with the launch of Carbon Drive Red, a series of limited edition red belts that accentuate the bike industry trend of color-matching components and frame highlights. Gates partnered with top lifestyle brands Schindelhauer, Budnitz, and Flying Machine to commision some red hot bikes for this limited edition release of Carbon Drive Red, and with Spot Brand, which has launched it's Acme Open. You can find more information on Carbon Drive Red here: http://www.gatescarbondrive.com/products/red-belt

Gates 2014 Holiday Hours

Gates Corporation offices will be closed 12/24, 12/25, 12/31, and 1/1. As a reminder, normal M-F hours are 7-4 MST.

From the entire Product Application team, Happy Holidays!

Thursday, December 18, 2014

PAE Videos

Have you ever wondered how to use the Sonic Tension Meter, or how to install a Poly Chain drive? Well guess what, we have videos that show you what you need to know on these subjects and many more. And the best part is that you can access them from your computer, your phone, or anywhere you can get on YouTube. Check them out here: https://www.youtube.com/user/GatesPT

Tuesday, December 9, 2014

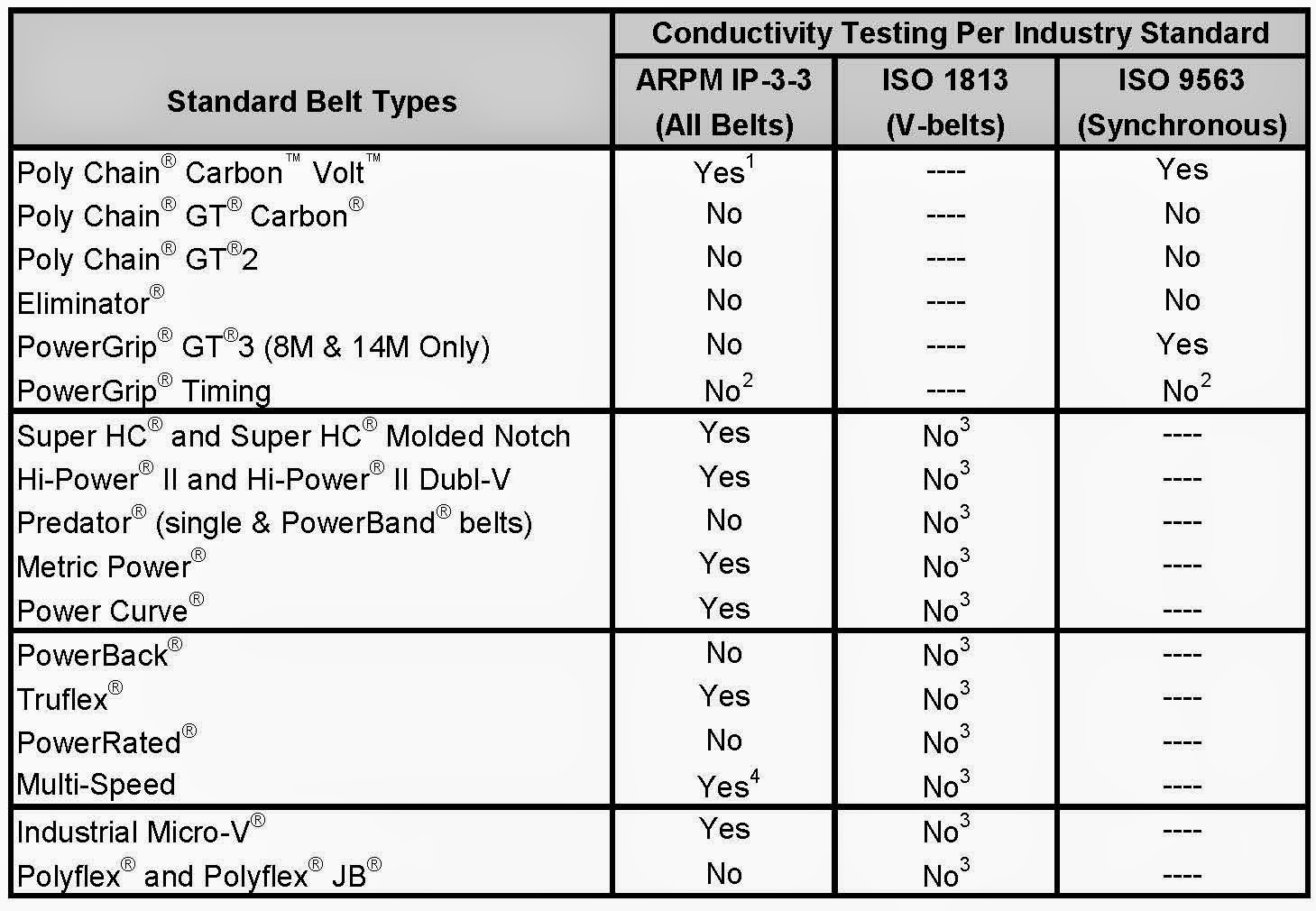

Gates Belts and Belt Conductivity Standards

We often receive questions as to whether our belts are conductive or not, or how they comply with industry standards. The following table includes a listing

of Gates belts and their certification status for belt

conductivity:

1 Not

tested ARPM IP-3-3

2 Static conductive made-to-order belts are

available

3 Not tested to ISO 1813

4 Includes only full banded 9899 prefix

construction

Feel free to contact Gates Product Application Engineering at ptpasupport@gates.com or 303-744-5800 with questions.

Tuesday, December 2, 2014

Defining Belt Drive Efficiency

Belt energy losses are typically considered in terms of shaft speed and torque:

Torque losses occur due to friction and bending stresses. Speed losses result from belt slippage and creep. Note that slip is only a factor for V-belt drives, as it does not occur in synchronous belt drive systems.

Efficiency (%) = [(Output Torque X Output RPM) / (Input Torque X Input RPM)] X 100

Torque losses occur due to friction and bending stresses. Speed losses result from belt slippage and creep. Note that slip is only a factor for V-belt drives, as it does not occur in synchronous belt drive systems.

An effective way to remember this hose selection criterion is to

remember the word STAMPED.

S T A M P E D

S = Size

T = Temperature

A = Application

M = Material to be Conveyed

P = Pressure

E = Ends or couplings

D = Delivery (volume)

T

Temperature

When selecting a replacement assembly, two areas of temperature must be considered. These are fluid temperature and ambient temperature. The hose selected must be capable of withstanding the minimum and maximum temperature of the system. Care must be taken when routing hose near hot manifolds, and in extreme cases, a heat shield may

be advisable.

Actual service life at temperatures approaching the recommended

limit will depend on the particular application and the fluid being used in the hose. Intermittent (up to 10 percent of operating time) refers to momentary temperature surges. Detrimental effects increase with increased exposure to elevated temperatures.

STAMPED - M (Material)

Some applications require specialized oils or chemicals to be conveyed through the system.

Hose selection must ensure compatibility of the hose tube, cover, couplings and O-rings with the fluid used. Additional caution must be exercised in hose selection for gaseous applications where

permeation can occur.

Permeation, or effusion, is seepage through the hose resulting in loss of fluid.

This may occur when hose is used with fluids such as (but not limited to):

• Liquid and gas fuels

• Refrigerants

• Helium

• Fuel oil

• Natural gas

Consider whether there are potential hazardous effects of permeation through the hose, such as explosions, fires, and toxicity.

Refer to applicable standards for specific applications such as fuels and refrigerants.

If gas permeates through the tube, consider pin-perforated covers to prevent gas build-up under the cover. Also consider the compatibility of the system fluid not only with the tube, but also with the braid, cover, fittings, and other components since permeation may expose the entire hose assembly to the system fluid.

Cover Perforation of Hydraulic Hose

Cover perforation of rubber covered hydraulic hose is required when air or other gases exist in a hydraulic or high pressure hose system. Without perforating, cover blisters or bubbles destroy protective capacity of the rubber cover and result in the deterioration of the reinforcement. Perforation is not required on textile covered hose because the porous textile cover allows gas to escape. If the system has low or medium pressure requirements, C5-type textile-wire-textile hose is an excellent recommendation. If air or other chemically acceptable gases are present in a fluid system and rubber covered hose is not perforated, gas migrates through the tube and reinforcement. It gathers beneath the cover, overcomes adhesion between reinforcement and cover and creates blisters or bubbles. Neither the rubber tube, cover, nor reinforcement suffers chemical ill effects from this action. But, blisters are cavities where moisture can collect and cause rusting or other deterioration of reinforcement. When wire reinforcements are sufficiently weakened by rust, hose fails when pressurized. If blisters are broken, cavity can collect additional dirt and moisture-collecting residue, making the corrosion problem worse. Correctly perforating rubber cover allows gas to escape without creating blisters or destroying protection provided by the cover. Perforation is achieved by pin-pricking small holes in the cover at close intervals along the total length of the hose assembly and around its circumference. Only the cover is perforated, not the tube or reinforcement. Rubber covered hydraulic hose can be ordered factory-perforated or Gates Power Line Perforators (7482-6565 or 7482-6566) are available. Remember, any gas of fluid conveyed in hydraulic hose must be compatible with the hose tube and cover. Always refer to the chemical resistance table if there are questions as to compatibility.

Tuesday, November 25, 2014

Gates Product Application on YouTube

Have you had a chance to check out our latest instructional and educational videos on YouTube? We have recently added several videos including those pertaining to transfer hose, hydraulics, crimping machines, and even hose cutters. If you have never looked at the Product Application page or simply haven't visited the site in a while, you can do so by following the link below.

www.YouTube.com/GatesPT

www.YouTube.com/GatesPT

For any additional

questions feel free to look through our other blog topics or contact us at ptpasupport@gates.com or

303-744-5800.

Tuesday, November 11, 2014

Gates Pulley Specifications

Detailed drawings and dimensions of Gates pulleys are shown in drive design manuals and online at www.Gates.com/PartView.

It's very important to understand that the details shown which do not affect drive function may be changed without notification. If a specific construction or material is needed for your pulley then it must get sourced through our Made to Order Metals department.

It's very important to understand that the details shown which do not affect drive function may be changed without notification. If a specific construction or material is needed for your pulley then it must get sourced through our Made to Order Metals department.

Minimum Belt Wrap and Tooth Engagement

Did you know that synchronous belts need a minimum amount of

wrap along with a minimum amount of teeth in mesh to transmit rated loads? The minimum teeth required in mesh to achieve

rated drive capacity is 6 teeth.

Anything less than 6 teeth reduces rated capacity significantly. In fact, for each tooth less than 6, you lose

20% of the rated load! This means at 4

teeth, you’re already down 40% of the rated load capacity! And as mentioned above, this isn’t the whole

story. Even if you have 6 teeth in mesh,

but you have less than 60 degrees of wrap, you may have belt problems. This really only applies to drives with more

than two shafts. Idlers that do not

transmit load do not have a minimum tooth engagement or degree of wrap

required.

Wednesday, November 5, 2014

Industrial Hose Service Life

All rubber products, including Industrial hose assemblies,

have a limited life on a given application. Assuming the correct hose has been

selected for the application, this service life can be adversely affected by

many variable conditions. The major ones are:

o

Exposure to severe external abuse such as

kinking, bending, high end pull, crushing or abrasion

o

Exposure to higher than rated working pressures

or to high surge pressures

o

Exposure to higher than rated temperatures

o

Misapplications or exposure to corrosive liquids

or gases outside the range of suitable applications.

External abuse –

hoses should be placed where they will not be run over by equipment or

subjected to high end pull. Hoses should not be bent below recommended minimum

bend radius. This could result in kinking the hose or reducing its pressure

resistance. Large diameter hoses also may require additional support to reduce

the external abuse

Hose and system pressures

– In establishing and determining pressures related to hose and the systems to

which they are applied, it is necessary to consider separately the characteristics

of the hose and the system.

o

The system (or device or applications) can have

several pressures depending on pressure sources and surges imposed by the

operator or mechanical components.

o

A given hose has a fixed characteristic with

respect to the pressure it can withstand (and how it is applied) and still give

satisfactory life

High Temperatures

- The allowable temperature ranges for industrial hoses are shown on the High Temperature

Ranges page. These are for product temperatures and should not be exceeded.

High temperatures can degrade rubber stocks very quickly resulting in short

service life. Where external temperature are higher than normal ambient,

contact your Gates field representative for recommendations.

Misapplications –

All industrial hoses are designed for certain specific application or related

application. They should not be used for any other applications.

Hose Information

– Refer to the Gates Industrial Hose Catalog for detail of hose constructions

and physical characteristics. These are shown in the data pages and include

such items as rated working pressure, vacuum rating, maximum bend radius, and

static conductivity.

Internal Abrasion

– For applications of a highly abrasive nature where the hose makes one or more

bends, the hose should be rotated 90 degrees periodically to lengthen service

life.

The hose manufacturer established, through design and

testing, the recommended rated working pressure for the hose. It is the

responsibility of the user to accurately determine the system pressure. Steady

state pressure can be measured readily by gauges. Surges are difficult to

measure and may require the use of electronic pressure pickup devices. Also,

surge values depend on so many variables that a series of tests are usually

required to obtain a valid set of readings. However, if there are extreme

surges in the normal operation or if there is the likelihood of abnormal

operation of the system, the magnitude must be determined.

Considering the recommended rated working pressure of the

HOSE and the various pressures of the SYSTEM, the hose is matched to the system

using proper application engineering principles. End terminations may reduce

the rated working pressure of hose assemblies. Refer to coupling manufacturer

for recommendations.

Temperature - Safe Hose Selection

An effective

way to remember this hose selection criterion is to

remember the

word STAMPED.

S = Size

T = Temperature

A = Application

M = Material to be Conveyed

P = Pressure

E = Ends or couplings

D = Delivery (volume)

Temperature (T)

When selecting a replacement assembly, two areas of

temperature must be considered. These are fluid temperature and ambient

temperature. The hose selected must be capable of withstanding the minimum and

maximum temperature of the system. Care must be taken when routing hose near

hot manifolds, and in extreme cases, a heat shield may be advisable.

Actual service life at temperatures approaching the recommended

limit will depend on the particular application and the fluid being

used in the hose. Intermittent (up to 10 percent of operating time) refers to

momentary temperature surges. Detrimental effects increase with increased

exposure to elevated temperatures.

Tuesday, October 28, 2014

New Drive Label Option In Design Flex Pro Software

Design Flex Pro is the most powerful belt drive design

software available in the industry. It

is widely used and is full of useful features.

Drive Detail Reports are well organized and contain a great deal of useful

information for designers as well as technicians installing belt drive systems.

The new version 3.10 includes a couple of added features

that users will find very helpful:

- Bushing bolt torque values for bushing installation have been added to Drive Detail Reports.

- A new drive label feature has been added as an output option on the Drive Detail Report screen.

The drive label feature allows users to output a .jpg file

containing a summary of the selected drive system including belt / sprocket / bushing part and product numbers

as well as detailed belt tensioning values for force/deflection and Sonic

Tension Meter measurements. This .jpg

file can be printed or imported into user documentation. A Drive Label example can be seen below:

Paper printouts of the label can be affixed to the equipment

for ready reference by technicians. Component

part and product numbers are available for re-ordering, and belt tension

recommendations are available for belt installations.

When printing the .jpg label files, select the landscape

mode for a full page printout. Install

dates should be added via. pen rather than computer at this point to prevent

printing issues.

The Quick Response code on the label will direct smart

phones to the www.gates.com/drivedesign

site where users will find ready access to Gates drive design tools and

technical resources.

Be sure to download and install or update to Design Flex Pro

version 3.10 to gain access to these new program features. Design Flex Pro just became even better! For additional information contact Gates Product

Application Engineering at ptpasupport@gates.com

or 303-744-5800.

Tuesday, October 21, 2014

PolyChain® GT® Sprocket Profiles

Sprocket profile information for 8mm and 14mm pitch PolyChain® GT® is available for purchase from Gates via the following link:

http://www.gatesstore.com/Gates_Synchronous_Sprocket_Templates

Items available for order include:

ptpasupport@gates.com

http://www.gatesstore.com/Gates_Synchronous_Sprocket_Templates

Items available for order include:

- 8mm and 14mm master transparencies for inspection

- 8mm and 14mm sprocket specification books that cover dimensions, tolerances, inspection procedure, etc.

ptpasupport@gates.com

Thursday, October 16, 2014

Storage Effects on Belts

Gates Belts may be stored up to six years if properly stored at temperatures less than 85 degrees Fahrenheit and relative humidity less than 70%.

For every 15 degrees Fahrenheit increase in storage temperature above the 85 degrees Fahrenheit recommended value, the time the belt can be stored without reduced performance decreases by one-half. it should be noted that belts should never be stored at temperatures above 115 degrees Fahrenheit.

At relative humidity levels above 70%, fungus or mildew may form on stored belts. This has minimal effect on belt performance, but should be avoided if possible.

When equipment is stored for longer than 6 months, the belt tension should be relaxed so that the belt does not take a set. In addition, the storage environment should meet the 85 degrees Fahrenheit and 70% or less relative humidity condition. If this is not possible, the belts should be removed and stored separately in a proper environment.

For every 15 degrees Fahrenheit increase in storage temperature above the 85 degrees Fahrenheit recommended value, the time the belt can be stored without reduced performance decreases by one-half. it should be noted that belts should never be stored at temperatures above 115 degrees Fahrenheit.

At relative humidity levels above 70%, fungus or mildew may form on stored belts. This has minimal effect on belt performance, but should be avoided if possible.

When equipment is stored for longer than 6 months, the belt tension should be relaxed so that the belt does not take a set. In addition, the storage environment should meet the 85 degrees Fahrenheit and 70% or less relative humidity condition. If this is not possible, the belts should be removed and stored separately in a proper environment.

For any additional questions feel free to look through our other blog topics or contact us at ptpasupport@gates.com or

303-744-5800.

Monday, October 6, 2014

508C Sonic Tension Meter

The Gates model 507C Sonic Tension Meter (product number 7420-0507) was recently replaced with the 508C Sonic Tension Meter (7420-0508). It is easy to identify the 508C model due to the green keypad, where the 507C model has a white keypad. The newer model works the same as the older model, and even uses the same attachments. The flat flexible sensor (7420-0205), inductive sensor (7420-0212), and cord sensor (7420-0206) will work with both Sonic Tension Meter models. The only two functional differences are the 508C does not have a low frequency filter, and the 508C has 40 data storage registers, where the 507C only has 20. Data storage registers are save slots that allow you to store mass, width, and span constants for specific applications. For more information about either model please click here.

S is for Size

An effective way to remember this hose selection criterion is to remember the word STAMPED. S T A M P E D: S = Size T = Temperature A = Application M = Material to be Conveyed P = Pressure E = Ends or couplings D = Delivery (volume). The inside diameter of the hose must be adequate to keep pressure loss to a minimum and avoid damage to the hose due to heat generation by excessive turbulence. To determine the replacement hose size, read the layline printing on the side of the original hose. If the original hose layline is painted over or worn off, the original hose must be cut and inside diameter measured for size. NOTE: Before cutting an original hose assembly, measure the overall assembly length and coupling orientation. This measurement will be required to build the replacement assembly or match the hose I.D. to the port size. Hose O.D. should not be used to identify the I.D. of the hose. Different hose constructions will vary with the wall thickness and O.D. The hydraulics industry has adopted a measuring system called Dash Numbers to indicate hose and coupling size. The number which precedes the hose or coupling description is the dash size. This industry standard number denotes hose I.D. in sixteenths of an inch (the exceptions are the SAE100R5, SAE100R14, and refrigerant hoses, where dash sizes denote hose I.D. compared to equivalent tube O.D.).

MegaCrimp and GlobalSpiral Couplings

Gates has several lines of couplings. Two of the most popular/most used are the MegaCrimp line used on Gates' medium pressure braided hydraulic hoses and the GlobalSpiral line used on Gates' high pressure spiral hydraulic hoses.

MegaCrimp couplings have a patented "C" insert, attached to the ferrule, that accommodates hose of different constructions and wall thicknesses. The insert's design ensures crimping forces are evenly distributed to form a concentric seal. The "C" insert simplifies inventory requirements since one MegaCrimp coupling size can accommodate various hose outside diameters, on both one and two wire braid hydraulic hose.

The key features for MegaCrimp couplings are their low profile, the "bite the wire" crimp, full stem insertion, full length crimp, 3x SAE requirements for standard impuse cycles, and TuffCoat plating for corrosion resistance.

GlobalSpiral couplings are specifically engineered to provide superior performance for extreme high pressure, high impulse spiral wire hydraulic hose applications. They can be used with all Gates MegaSys four and six spiral wire hose up to 8,000 psi. The two piece, no skive design reduces assembly time, labor, fabrication errors and contamination of the fluid power system. The work area stays clean, and the odors and dust normally created by skiving are eliminated. In addition, the two piece design reduces parts inventory by 30 percent because only one stem is required for all spiral wire hose types. The key features for GlobalSpiral couplings are the "bite the wire" crimp, the availability of over 30 thread configurations, and 2x SAE requirements for impulse cycles at 250 degrees F.

Friday, September 26, 2014

Relationship between HP, RPM, and Torque

When designing a belt drive, the load being transmitted is

one of the most important pieces of information that is needed. To properly describe the load, there are two

key pieces of information: HP and RPM, or Torque (Q) and RPM. RPM is important in either case to quantify

the load. Believe it or not 10hp at

1000rpm is not a very high load compared to 10hp at 100rpm. Here are the equations that relate one to the

other:

This is for torque in in*lbs

HP = (Q x RPM) / 63025

Q = (HP x 63025) / RPM

This is for torque in ft*lbs

HP = (Q x RPM) / 5252

Q = (HP x 5252) / RPM

If we use the example above, the torque for 10hp at 1000rpm

is 630.25 in*lbs, where the torque for 10hp at 100rpm is 6302.5 in*lbs, a

pretty big difference for your belt drive!

Monday, September 22, 2014

Introducing Poly Chain® Carbon™ Volt ™

Belt drive applications are sometimes located in potentially

explosive atmospheres requiring belts to be static conductive. This allows naturally generated static

electric charges to be dissipated into sheaves, shafts, bearings, etc. and safely

to ground. Static conductive belts are

required by various industries, such as the petrochemical industry. Until recently, static conductive synchronous

belts were only available on a made-to-order basis. PowerGrip® GT3® belts in 8mm

and 14mm pitches are now static conductive to ISO 9563. And Poly Chain® Carbon™

Volt™ has just been introduced.

Poly Chain belts have never met industry standards for belt conductivity until now. Poly Chain Carbon Volt belts utilize several

patented technologies that enable excellent conductive properties that are

retained much longer than any other belt available. Industry standards for belt conductivity (ISO

9563 for synchronous belts, ISO 1813 for V-belts, ARPM IP-3-3 for all belt

types) apply only to new belts. There

are no belt conductivity requirements for belts that are in service, and belt

conductivity properties are known to decline over time at a fairly significant

rate. Testing has shown Poly Chain

Carbon Volt conductive properties to retain much longer than conventional

belts, so are considered to be much safer over time.

Poly Chain Carbon Volt belt testing has not yet shown belt

conductivity properties to fall below ISO 9563 standards, so it may not be

unreasonable for conductivity to be retained throughout belt life. Even so, grounding brushes are always

recommended as a secondary means of dissipating static electric charges in belt

drive systems located in potentially hazardous environments.

Poly Chain Carbon Volt belts can be made in any standard

size, but are not yet available in every size.

Check with your local Gates Industrial Distributor for availability. If you have any questions, contact Gates

Product Application Engineering at ptpasupport@gates.com

or 303-744-5800.

Wednesday, September 10, 2014

Safe Hose Selection

Proper hose selection is critical to a safe hydraulic system, hose

performance characteristics and service application an easy method is used to properly select a hydraulic hose.

An effective way to remember this hose selection criterion is to

remember the word STAMPED.

S T A M P E D

S = Size

T = Temperature

A = Application

M = Material to be Conveyed

P = Pressure

E = Ends or couplings

D = Delivery (volume)

The first step in having a safe hydraulic system is selecting

components that meet your needs. Compromises in hose selection

may put you in danger, as well as affect the performance and life

of your system. The decision may work for the short run, but may

not be a good long-term decision.

Remember, the most important thing is your safety.

Most hydraulic systems should be designed with a 4:1 safety factor

(burst test pressure vs. maximum recommended working pressure).

However, some applications may have different standards (examples: water blast, jack hose).

Tuesday, September 9, 2014

Standard V-belt Sheaves for Round Belts

The table below summarizes the standard V-belt sheave options for round belts.

Light Duty V-belt

Sheave Size

|

Heavy Duty V-belt

Sheave Size

|

Closest Fit

Round Belt(s)

|

0

|

-

|

3/16"

|

1

|

-

|

5/16"

|

2

|

A

|

3/8, 7/16"

|

3

|

B

|

1/2", 9/16"

|

-

|

C

|

11/16", 3/4"

|

-

|

D

|

1-1/16"

|

Thursday, August 21, 2014

EZ Align Battery Life

Occasionally we get questions about battery life on our EZ Align tool. Typically it is not a problem, but not all AAA's are created equal. For best battery life, we recommend Lithium batteries.

Tuesday, August 19, 2014

Calculating Pressure Drop for a Hose Assembly

With some basic system information, reliable pressure drop approximations may be readily calculated.

First, determine the applicable mechanical components and fluid for the analysis. Completing this process one hose assembly at a time is recommended.

Next, enter those values into the Gates online pressure drop calculator (Fluid Flow Calculator). The link to the calculator is:

http://www.gates.com/catalogs-and-resources/resources/repository/engineering-business-applications/fluid-flow-calculator/fluid-flow-calculator .

Required Hose Assembly information to complete the calculations includes Inside Diameter, Length, Couplings, and Adapters.

Required Fluid Information includes Density, Viscosity, and Heat Capacity. These may be estimated with fluid type and temperature. Examples of Specific Gravity and Viscosity for some common fluids are:

Water- Specific Gravity 1.00, Viscosity 1.0;

Gasoline- Specific Gravity 0.71, Viscosity 0.5;

Ethyline Glycol- Specific Gravity 1.12, Viscosity 19.5

Check Your Drive Before You Wreck Your Drive

When a drive experiences problems it's easy to assume the belt is defective, or that the standard belt construction is underrated for the application. Before blaming the belt or requesting a made-to-order belt construction, please consider the pie chart below (click to enlarge). There are many factors that can lead to premature belt failure. This chart illustrates the most common sources of drive problems. Download the Belt Drive Preventive Maintenance and Safety Manual for more information. Also, check out our failure analysis blogs for V-belt and synchronous drives to troubleshoot drive problems.

Monday, August 18, 2014

Crimper Preventive Maintenance

As with other types of equipment, it is very important to properly maintain crimpers. A typical crimper is a hydraulic ram that uses fluid under pressure to extend the ram and crimp the fittings. Fluid flows from the pumps to the cylinder under pressure. This extends the piston, rod and pusher down on the die cone. The die cone is sloped to receive tapered die fingers. As the die cone is pushed by the hydraulic ram, the die fingers are forced (perpendicular) inward. The set of die fingers completely surrounds the ferrule to provide an even crimp. Though there are many types and configurations of crimpers, i.e., vertical (bottom or top loading), horizontal or angled, the basic principle of operation is the same. Pumps do not have to be electronically driven. They can be manual or air driven. Care should be taken to properly set up and maintain these crimpers.

Lubrication

Lubricants should be reapplied to metal-to-metal sliding surfaces whenever the surface becomes shiny. Use only a very thin coat of Molycote lube. Failure to do so reduces the life of the dies and cone. Excessive wear on these components produces poorly performing hose assemblies that could blow

apart and result in injury.

Calibration

Check the crimper’s calibration at least monthly or whenever you notice a change in crimp diameter. This is critical for repeatedly producing accurate hose assemblies. Be aware that some machines calibrate automatically.

Fluid Level

Proper fluid level in the reservoir (tank) is important for maximum crimp stroke as well as keeping air from getting into the system. Make sure the fluid is within 1/2” from the top of the tank opening.

Die Wear and Storage

Check the dies’ sliding and crimping surfaces for wear or damage during use. Look for nicks, chips, racks, gouges and/or other signs of wear. Replace die if any of these exist. Proper storage and lube will extend their service. Store in stable racks or in original

Cleaning

Hydraulic fluid and lubricants can pickup dirt and debris. Clean off any buildup using a clean shop rag. Buildup can damage crimper components and produce inaccurate crimped assemblies.

Tuesday, August 5, 2014

Precision Length Matching For Industrial V-Belts

Gates manufactures all industrial V-belts within industry standard

belt length and belt matching tolerances. All industrial V-belts included in the V80 no-match system are marked with a distinctive "V80" symbol.

The manufactured lengths of industrial V-belts with a

V80 marking are within industry matching tolerances with all Gates belts in the same

size. This eliminates the need for

special belt matching practices for multiple belts used in sets.

Small belt tension variations visible in new belt sets is

normal. Tensioning new belts to

recommended levels and running them in for 24 to 48 hours generally equalizes

all belt lengths and belt tension levels.

After the initial run-in period they should be re-tensioned to the level

recommended for "used" belts.

Occasionally there are special applications with unusually

sensitive performance requirements, or users may be unusually sensitive to belt

tension variations in new belt sets. In

these cases, “precision matched” belt sets may be requested. Precision matched belt sets require hand

measuring, sorting and handling to identify belt lengths within 0.15”, so are

priced at a premium level and may require some lead time.

Precision matched belt sets require a run-in period of 24 to

48 hours and re-tensioning, just like conventional V80 matched belt sets. Other than some potential reduction in belt

vibration during the short run-in period, precision matched belt sets are

expected to perform nearly identically to conventional V80 matched belt sets.

For additional information about any of this, feel free to

contact Product Application Engineering at ptpasupport@gates.com or at

303-744-5800.

Tuesday, July 29, 2014

Calculating Pitch Diameter for Synchronous Sprockets / Pulleys

If you know the number of sprocket grooves and the belt pitch (distance from the center of one belt tooth to the center of the next), you can easily calculate sprocket (or pulley) pitch diameter:

Metric Pitch Belts / Sprockets:

sprocket pitch diameter (in) = 0.012532 × pitch (mm) × # grooves

Timing Belts / Pulleys:

pulley pitch diameter (in) = 0.31831 × pitch (in) × # grooves

Pitch and number of grooves can typically be identified using the part number:

Metric Pitch Example - 14MX-40S-68:

sprocket pitch diameter (in) = 0.012532 × 14 mm × 40 grooves = 7.018 in

Timing Example - TL40H150:

pulley pitch diameter (in) = 0.31831 × 0.50 in × 40 grooves = 6.366 in

Metric Pitch Belts / Sprockets:

sprocket pitch diameter (in) = 0.012532 × pitch (mm) × # grooves

Timing Belts / Pulleys:

pulley pitch diameter (in) = 0.31831 × pitch (in) × # grooves

Pitch and number of grooves can typically be identified using the part number:

Metric Pitch Example - 14MX-40S-68:

sprocket pitch diameter (in) = 0.012532 × 14 mm × 40 grooves = 7.018 in

Timing Example - TL40H150:

pulley pitch diameter (in) = 0.31831 × 0.50 in × 40 grooves = 6.366 in

Robert Hight Wins Again With the Help of Gates Poly Chain Blower Belts

In case you missed it, July 18th marked the

beginning of the 35th annual Mopar Mile-High Nationals in Morrison,

Colorado. As you may know, Gates is a

proud sponsor of the John Force Racing team and they must have been feeling the

local Gates support because 3 of the 4 drivers in the finals for

Top Fuel Dragster and Top Fuel Funny Car were members of the Johns Force Racing

Family (Brittany Force, John Force, and Robert Hight).

The Top Fuel Dragster final had Brittany Force racing J.R.

Todd. Brittany went into the race

hungry for her first Top Fuel Dragster national win and was poised to do so

with her confidence and exceptional race car however she was outrun after what

appeared to be a loss of power in a few cylinders. Brittany is quickly becoming one of the best

drivers in Top Fuel Dragster and it won’t be long before she and her entire

team take home John Force Racing’s first Top Fuel Dragster Wally.

The Top Fuel Funny Car final pitted two of the best drivers

in the field in John Force and Robert Hight against one another. This was set to be a great drag race with John

Force and Robert Hight qualified number 1 and number 2 respectively and John

setting a track record during the first days qualifying sessions. Robert was able bring home the Wally with a stellar

pass while John was unable to maintain traction and went up in smoke around the

330 ft. mark. This was Robert’s 5th win of the season and he is now firmly atop the Top Fuel Funny Car points and

with this win also clinched a spot in the Top 10 Countdown to the

Championship. Robert’s winning pass and post-race

interview can be seen HERE in which Robert thanks the Gates Corporation for

helping him get another win.

Wednesday, July 23, 2014

Made-To-Order Metals

When standard metal

drive components won’t work, call the Gates Made-To-Order Metals Team. Our dedicated made-to-order metals staff

specializes in providing prototype and production pulleys, sheaves, and

sprockets to meet your design expectations and requirements. No order is too large or too small.

- Drive components are available in a variety of bores, styles, materials and finishes including:

- Pulleys, Sheaves and Sprockets — All Gates Synchronous Profiles and Pitches, Micro-V® and V-Belt‚ Plain or Profiled Idlers

- Bores — Plain, Straight, Tapered, Splined or any Special Bore. Manufactured to accept Taper-Lock,® Ringfeder,® QD, Torque Tamer, Trantorque® or other Special Bushings

- Styles — Bar Stock, Idlers, Ringfeder Connections, Torque Tamers, Custom Configurations, Special Hubs and more

- Materials — Aluminum, Steel, Ductile, Cast Iron, Phenolic, Stainless Steel or Plastics

- Finishes — Hard Coat, Food Grade, Zinc, Black Anodize, Nickel Plating, Custom Plating or any Special Coatings

- Processes — Hob Cutting, Shaper Cutting, Die Casting and Molding

- Services include sub-assembly, press bearings,

sprocket/bushing balancing and index marking.

- CAD drawings accepted.

- Quoting usually within 48 hours.

If you are unsure as to

what considerations need to be made for your non-standard metal component then the

Gates Metals Technical Guide is a great resource to help you further understand

the available options and their relevance to your specific needs. Of course our made-to-order metals team can

always be contacted at 800-709-6001 or MakeMyMetal@Gates.com to answer any questions and develop a quote for your metal drive components needs.

Tuesday, July 15, 2014

Abrasion Resistant Covers - Tough Covers That Extend MEGASYS Hose Life

Gates abrasion-resistant covers available on MegaSys hoses are tested and proven to stand up under the harshest operating conditions. These convers increase hose service life, lower maintenance and replacement costs, and eliminate the need for costly hose protectors such as spring guards and nylon sleeves.

MegaTuff Hose Cover

• Super-tough cover solves abrasion and wear problems

• 300 times the abrasion resistance of standard hose covers

• Tested to 1,000,000 cycles without failure

• Resistant to oil, ozone and UV rays

• Outperforms any other abrasion-resistant hose covers on the market today

XtraTuff Hose Cover

• Mid-range abrasion-resistant cover

• 25 times the abrasion resistance of standard hose covers

• Resistant to oil, ozone and UV rays

Pressure Drop

What Is Pressure Drop?

Friction is defined as the resistance an object encounters in moving over another; solids, liquids, and gases all exhibit friction in their motion. In hose and piping systems, the result of this friction is pressure drop and heat generation that may be accurately estimated with engineering models.

Why Does Pressure Drop Matter?

If there is excessive pressure drop in a system, pumps will have to work harder, use more energy, and the working fluid will increase in temperature. Depending on the source of the additional pressure loss, it could raise the whole system pressure, increase wear, and introduce potentially dangerous over-pressure conditions, render some tools or equipment functions inoperable because of inadequate operation pressure, or create damaging cavitation and loss of net positive suction head (NPSH).

What Affects Pressure Drop?

The factors which contribute to pressure loss may be broken down into two general categories: mechanical components and fluid properties. Mechanical components such as valves, flow meters, quick disconnects, adapters, couplings, tubing, hose, etc., all contribute to pressure loss. The amount of pressure loss in mechanical components is impacted by criteria such as cross-sectional area, internal surface roughness, length, bends, and geometric complexity. Fluid properties such as density, viscosity, heat capacity, and bulk modulus will also contribute to pressure loss. Fluid properties are impacted by temperature, pressure, contamination, and time. Fluid velocity has the most impact. Fluid velocity is a direct product of flow rate and cross-sectional area.

What Can Be Done to Reduce Pressure Drop?

• Check pressure drop when non-identical replacement parts or ongoing system problems are observed.

• Use straight adapters and bent-tube couplings whenever possible.

• Replace worn parts and old fluids.

• Lower the fluid velocity.

Thursday, July 10, 2014

Tri-Power PowerBand Belts Now in Stock

It's the best of both worlds! Premium ethylene rubber, notched, classical section V-belts with a PowerBand construction.

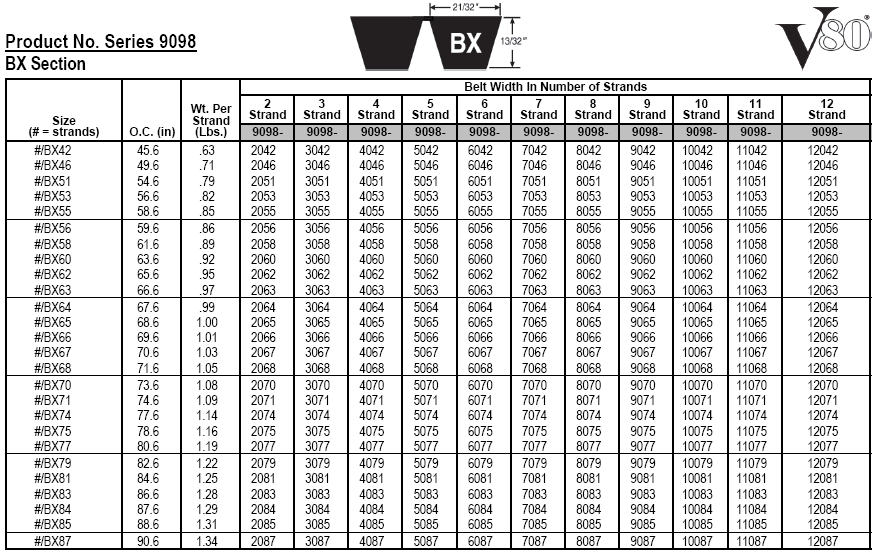

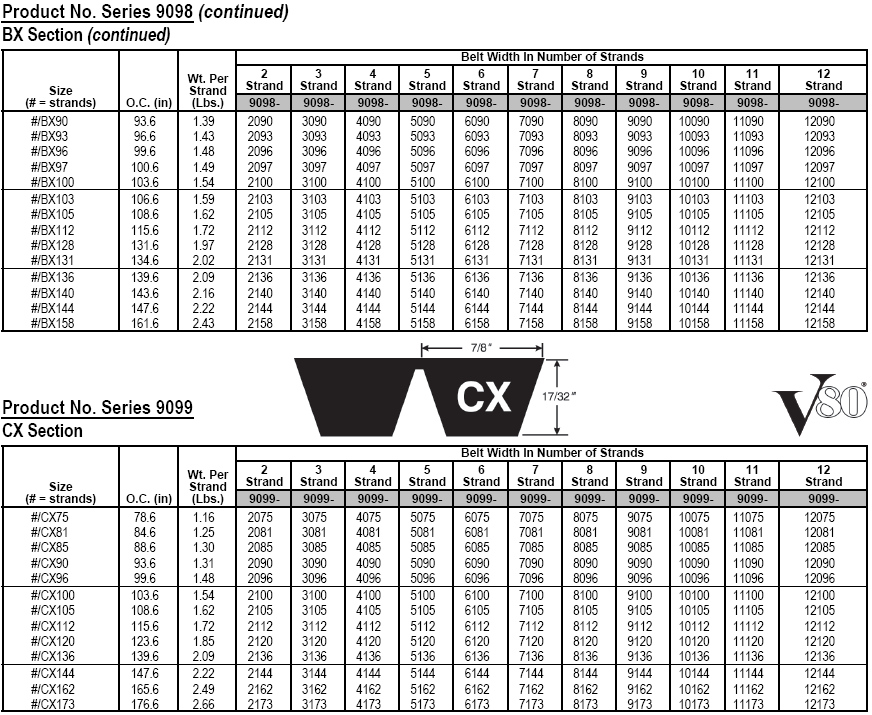

Standard/stock belt sizes are shown below. Click the images to zoom in. Custom sizes can be made to order (check with Product Application Engineering).

Standard/stock belt sizes are shown below. Click the images to zoom in. Custom sizes can be made to order (check with Product Application Engineering).

Tuesday, July 8, 2014

When Belts Fly: The Gates Nicolai MTB Team Elevates Carbon Drive to New Heights

You've probably heard it before, Gates belts are not allowed on anything that leaves the ground. No plane or UAV applications. Well, this application is just a little different, and while it is being demonstrated as leaving the ground, it doesn't quite qualify as a plane: When Belts Fly: the Gates Nicolai MTB Team Elevates Carbon Drive to New Heights

Thursday, June 19, 2014

A/B Multi-Duty® Sheave Use

Individual V-belts do not require exact groove spacing to properly operate. Therefore, both A and B-section single V-belts can be used with Gates Multi-Duty combination sheaves.

However, PowerBand® joined V-belts require very specific groove spacing for proper fit and operation. Gates Multi-Duty® combination sheaves use B-section groove spacing, making only B-section PowerBand V-belts compatible.

Sheaves that may be used with A-section PowerBand V-belts are available through Gates Made-to-Order Metals (www.gates.com/mtometals/).

However, PowerBand® joined V-belts require very specific groove spacing for proper fit and operation. Gates Multi-Duty® combination sheaves use B-section groove spacing, making only B-section PowerBand V-belts compatible.

Sheaves that may be used with A-section PowerBand V-belts are available through Gates Made-to-Order Metals (www.gates.com/mtometals/).

Labels:

combination,

Hardware,

Multi-Duty,

sheaves,

V-belts

Friday, June 13, 2014

www.Gates.com Shortcuts

If you have been on our website recently, you may know that

it has changed pretty significantly.

What you may not know is that many of our shortcuts still work. Here are a couple of direct

links that may help you navigate the website faster:

Engineering

Design Flex

Design IQ

PartView

Distributor Locator

Thursday, June 12, 2014

EZ Align Green Laser Alignment Tool

The Gates EZ Align laser alignment tool is the best available

in the industry for measuring belt drive alignment. EZ Align shows misalignment in three planes,

and the unique reflective technology multiplies angular shaft misalignment for much

more accurate measurement. It is fast

and easy for one person to use and is very durable for use in industrial

environments.

The original EZ Align laser tool utilized a high quality red

laser, but it is now available with a more powerful green laser. The green color improves visibility for outdoor

use in sunlight, as it is 10 times brighter than the original red laser. The range has been extended from approximately

6 feet for the red laser to 15 feet or better for the green laser. The following figures illustrate the original

EZ Align and EZ Align Green laser tools.

EZ Align Green Laser Alignment Tool

Original EZ Align Laser Alignment Tool

While the original EZ Align laser tool works well indoors,

the visibility of EZ Align Green in sunlight is a dramatic improvement. EZ Align Green is the laser alignment tool of

choice for use in sunlight, even with a modest price increase.

For further information or assistance, feel free to contact

us at ptpasupport@gates.com or at

303-744-5800.

Belt Characteristics

When designing a power transmission system, it is important

to consider the environmental conditions the belt will be exposed to. This includes, but is not limited to; ambient

temperatures, oil exposure, and static conductivity requirements. These factors are often overlooked and can

result in an otherwise appropriately designed system performing inadequately, not meeting the required specifications, or failing. Below is a list of Gates standard line belt characteristics. This

should be used as a reference whenever a new belt drive is designed or the

drive environmental requirements are in question.

For any additional questions feel free to contact us at ptpasupport@gates.com or

303-744-5800.

Wednesday, June 4, 2014

Fluid Power: Don't Mix and Match!

A 3,000 psi coupling on a 3,000 psi hose does not always equal a 3,000 psi assembly. One of the most important and often times overlooked factors in hydraulic hose assembly performance is the hose/coupling interface. You can’t just design a hose, you can’t just design an coupling. You must design a system. Unless you have a hose and coupling specifacally designed for each other, you may end up with a hose assembly with a lower pressure rating, reduced life, or even worse, a catastrophic failure. Hose outside diameter and crimp outside diameter are only two of the variables affecting assembly performance. As variation or tolerances increase even slightly for each component a significant reduction in hose assembly life is guaranteed and the risk for catstrophic failiure increases.

The next time you grab any hose and a coupling ask youself: Who is the manufacturer of these components? Have these components been designed together? Validated together? And if not, what are the risks that I am assuming? Am I willing to accept an assembly with a guarantee for reduced impluse life and performance? Am I willing to risk catastrophic failure?

Monday, June 2, 2014

Fluid Power: Use of Adapters Part II

Adapters can be used to make installation and orientation easier. Be aware, however, that adapters can also be a potential leak point. Adapters can be used in the following situations:

A. To change to a different thread configuration, including international threads.

B. As a rule of thumb, it is better to use a straight adapter and bent tube coupling than an angled adapter and straight hose end. Using a straight adapter and bent tube coupling promotes laminar flow and reduces pressure drop compared to an angled adapter/straight hose end.

When using adapters, the preferred method is to install the adapter first, and then the hose assembly.

Tuesday, May 27, 2014

What do you want to read?

To date, we have published 178 blog posts! There are a lot of different topics to read about. If there's something you want us to blog about then let us know by using the comment section below.

Tuesday, May 13, 2014

Got Questions About Interchanging and Replacing Belts?

A sizable percentage of inquiries directed to our Product

Application Engineering Group are for belt replacements on all types of

equipment and vehicles. While we would

like to help with all of these inquiries, our abilities are limited so please

refer to the following guidelines.

Belts For Original

Equipment Manufacturers

Gates works directly with many original equipment manufacturers

to develop belt drive systems and special belt constructions that meet their specific

system requirements. Manufacturers often

assign their own unique part numbers to these special belts and differ from

industry standard belt part numbers.

While Gates supplies many special belts, specific details about them are

considered to be proprietary and belts are only available from original

equipment manufacturers directly.

Replacement Belts

For Industrial Equipment

We are best equipped to identify and interchange

industrial belts used in industrial applications. This can be as simple as recognizing industry

standard belt designations, or may require evaluating measurements and identifying equivalently sized standard industrial belts.

For assistance identifying industrial belt part numbers, go

to http://www.gates.com/. Note that the web page comes up with the “Parts/Interchange”

tab highlighted. Click the “Industrial”

button and enter the part number to interchange.

Replacement Belts

For Automotive Applications

We are not equipped to assist with belt interchanges

for automotive applications. These

applications include all front end accessory drives for cars, trucks, buses and

farm-construction equipment, etc. and engine camshaft drives.

For on-line assistance, go to http://www.gates.com/. The web page comes up with the “Parts/Interchange”

tab highlighted and the “Automotive” button activated. Enter the part number to see if an

interchange can be identified. Or click

on “Search by Application” to access the Part Locator Tool.

For personal assistance contact the Automotive Product

Application Group directly at (303) 744-5651 or at apateam@gates.com.

Replacement Belts for

Outdoor Power and Recreational Equipment

We are not equipped to assist with belt

interchanges for outdoor power and recreational equipment. Examples of these applications are lawn and

garden equipment, and sport and utility vehicles.

For on-line assistance, go to http://www.gates.com/. The web page comes up with the “Parts/Interchange”

tab highlighted and the “Automotive” button activated. Enter the part number to see if an

interchange can be identified. Or click

on “Search by Application” to access the Part Locator Tool.

For personal assistance contact the Automotive Product

Application Group directly at (303) 744-5651 or at apateam@gates.com.

Replacement Belts

For Motorcycles

All belt drive components found on motorcycles as original

equipment are available through the original equipment manufacturer only. Gates does not offer replacement belts.

Belt drive components applied to motorcycles as aftermarket

components or kits are available from numerous motorcycle customizing and kit

manufacturers. Gates sells belts

directly to many of these manufacturers, as with original equipment

manufacturers, and does not offer replacement belts.

Hopefully this brief

overview of belt interchanging and replacement will help in identifying the

most direct and appropriate resources from Gates to help get you moving again. For questions feel free to contact us at 303-744-5800

or at ptpasupport@gates.com

Tuesday, May 6, 2014

Minimum Sheave Diameters for Nu-T-Link® Belting

When applying Nu-T-Link® belting, the minimum diameter recommendations should be followed to maximize belt performance. Nu-T-Link belts have the same diameter recommendations as the Gates Hi-Power® II product line.

Note: the above diameters are for belt performance only. NEMA recommendations should also be followed where applicable to protect the motor shaft and bearings.

Nu-T-Link

Part Number

|

Hi-Power® II

Cross Section |

Minimum

Recommended

Sheave Diameter

(inches)

|

NTL/A

|

A

|

3.0

|

NTL/B

|

B

|

5.4

|

NTL/C

|

C

|

9.0

|

NTL/D

|

D

|

13.0

|

Note: the above diameters are for belt performance only. NEMA recommendations should also be followed where applicable to protect the motor shaft and bearings.

Monday, May 5, 2014

Fluid Power: Use of Adaptors

Adapters can be used to make installation and orientation easier. Be aware, however, that adapters can also be a potential leak point.

Adaptors can be used in the followingsituations:

1. To avoid fitting orientation, use a straight fitting and an angle adapter on one end. This makes installation easier and eliminates the need for orientation. However, this requires more parts and increases the number of joints for potential leakage.

2. When jump-size fittings are not available, make the jump with anadapter.

3. To ease port connection and hose installation.

Advantages of Preventive Maintenance for Hydraulic Hose

There are several good reasons to begin a preventive maintenance program. Costly emergency repairs, production downtime and worker safety to name a few. The main objective of a preventive maintenance program is to identify component weaknesses before failure and loss of production.

Some people believe that PM actually should mean “predictive maintenance” rather than “preventive maintenance.” Preventive maintenance is especially important with hydraulic products. The high pressures and temperatures associated with hydraulics make hose and fitting maintenance as well as selection critical. If done correctly, the risk of injury and/or excessive, costly downtime decreases significantly. In addition, there is a growing awareness regarding costs associated with cleaning up a hydraulic spill (EPA). Combining top-quality Gates products with a regular preventive maintenance program will keep your equipment at maximum efficiency.

Thursday, May 1, 2014

Is your Lawn, Garden, and Agricultural Equipment ready for the Summer?

As summer approaches, it is time to start inspecting your lawn,

garden, and agricultural equipment to get them ready for the season ahead. One key component you will want to examine is

the belt drive system. Whether it is

powering the blade on your lawn mower or the auger on your harvester, the belt

drive components will wear out over time and can degrade through the winter

months. To ensure you are getting the

best performance and productivity from your equipment, it is best to replace

any worn belts, sheaves, sprockets or bushings before the equipment is

needed. This will give you peace of

mind that you will not be left with down equipment due to fatigued belts or

worn hardware.

Gates offers a variety of aftermarket and OEM specific replacement

parts for your equipment that will help ensure you are ready for the summer months. For any assistance with

any of our Lawn, Garden or Agricultural products, please contact our Automotive

Aftermarket team at 303-744-5651 or APATeam@Gates.com.

Thursday, April 17, 2014

PowerGrip GT3 Drive Design Manual

Gates is constantly looking to add innovative products to provide our distributors and our customers with the best quality and selection available. As part of that effort, single sided PowerGrip GT2 belts have been upgraded to PowerGrip GT3 constructions. An upgraded product line requires an upgraded drive design manual so for technical information on the new PowerGrip GT3 belts please download the drive design manual using the link below.

PowerGrip GT3 Design Manual

PowerGrip GT3 Design Manual

Wednesday, April 9, 2014

PowerGrip 5mm GT2 Aluminum Sprockets

Gates is now offering a selection of aluminum sprockets for

5mm pitch PowerGrip GT2 and GT3 belting. These sprockets will be offered

in both 9mm and 15mm widths. They are not offered in 25mm widths. While

the parts are not yet listed in our Industrial Power Transmission catalog, they

are listed in our new PowerGrip GT3 Drive Design Manual which you can find

here: http://www.gates.com/products/industrial/industrial-belts/product-application-engineering

It is very important to note that these sprockets have

LIMITED wear resistance with our 5mm PowerGrip GT belts, and INSUFFICIENT wear

resistance and load capacity for our 5mm Poly Chain belts. These

sprockets are also available in sizes down to 12 teeth. Our MINIMUM

sprocket tooth count recommendation for 5mm PowerGrip GT2/GT3 belting is 18

teeth. Going below this will significantly impact belt life.

For these reasons, these sprockets are best used for prototyping purposes.

Tuesday, April 1, 2014

Have You Seen The New gates.com Website?

Visit http://www.gates.com/

to see the new Gates website. This means

a new and fresh look along with new functionality. As with any major change, though, there are

improvements as well as things that don’t work the same way they used to, and saved

links that may not work any longer.

The main site features are included in the clean and concise

menu bars at the top of the main page.

The feature box located in the middle of the screen provides easy access

to some of the most popular sites.

Belt identification and interchanging tools are readily

accessible in the feature box as well as a “where to buy” tool and a site

search tool. The search engines in the site

are very fast and powerful, so are a great place to start when looking for new

information. Below the three promotion

boxes click on Popular Links for ready access to popular pages like the

PartView System, Design Flex Software, Design IQ Software and a series of fluid

power related sites.

Our Product Application Engineering page for industrial

power transmission products is located at:

http://www.gates.com/products/industrial/industrial-belts/product-application-engineering

or can be accessed by navigating to http://www.gates.com/drivedesign

as before. Our page includes contact

information and links to valuable engineering tools and sites as well as useful

drive design manuals, users manuals and related literature.

You can be assured that changes and improvements have and will

continue to be made to our new site.

After navigating the site a bit, hopefully new functionality,

improvements and faster screen loads will be seen.

For technical assistance or questions, feel free to contact

Product Application Engineering at 303-744-5800 or at ptpasupport@gates.com.

Subscribe to:

Posts (Atom)