If you know the number of sprocket grooves and the belt pitch (distance from the center of one belt tooth to the center of the next), you can easily calculate sprocket (or pulley) pitch diameter:

Metric Pitch Belts / Sprockets:

sprocket pitch diameter (in) = 0.012532 × pitch (mm) × # grooves

Timing Belts / Pulleys:

pulley pitch diameter (in) = 0.31831 × pitch (in) × # grooves

Pitch and number of grooves can typically be identified using the part number:

Metric Pitch Example - 14MX-40S-68:

sprocket pitch diameter (in) = 0.012532 × 14 mm × 40 grooves = 7.018 in

Timing Example - TL40H150:

pulley pitch diameter (in) = 0.31831 × 0.50 in × 40 grooves = 6.366 in

Tuesday, July 29, 2014

Robert Hight Wins Again With the Help of Gates Poly Chain Blower Belts

In case you missed it, July 18th marked the

beginning of the 35th annual Mopar Mile-High Nationals in Morrison,

Colorado. As you may know, Gates is a

proud sponsor of the John Force Racing team and they must have been feeling the

local Gates support because 3 of the 4 drivers in the finals for

Top Fuel Dragster and Top Fuel Funny Car were members of the Johns Force Racing

Family (Brittany Force, John Force, and Robert Hight).

The Top Fuel Dragster final had Brittany Force racing J.R.

Todd. Brittany went into the race

hungry for her first Top Fuel Dragster national win and was poised to do so

with her confidence and exceptional race car however she was outrun after what

appeared to be a loss of power in a few cylinders. Brittany is quickly becoming one of the best

drivers in Top Fuel Dragster and it won’t be long before she and her entire

team take home John Force Racing’s first Top Fuel Dragster Wally.

The Top Fuel Funny Car final pitted two of the best drivers

in the field in John Force and Robert Hight against one another. This was set to be a great drag race with John

Force and Robert Hight qualified number 1 and number 2 respectively and John

setting a track record during the first days qualifying sessions. Robert was able bring home the Wally with a stellar

pass while John was unable to maintain traction and went up in smoke around the

330 ft. mark. This was Robert’s 5th win of the season and he is now firmly atop the Top Fuel Funny Car points and

with this win also clinched a spot in the Top 10 Countdown to the

Championship. Robert’s winning pass and post-race

interview can be seen HERE in which Robert thanks the Gates Corporation for

helping him get another win.

Wednesday, July 23, 2014

Made-To-Order Metals

When standard metal

drive components won’t work, call the Gates Made-To-Order Metals Team. Our dedicated made-to-order metals staff

specializes in providing prototype and production pulleys, sheaves, and

sprockets to meet your design expectations and requirements. No order is too large or too small.

- Drive components are available in a variety of bores, styles, materials and finishes including:

- Pulleys, Sheaves and Sprockets — All Gates Synchronous Profiles and Pitches, Micro-V® and V-Belt‚ Plain or Profiled Idlers

- Bores — Plain, Straight, Tapered, Splined or any Special Bore. Manufactured to accept Taper-Lock,® Ringfeder,® QD, Torque Tamer, Trantorque® or other Special Bushings

- Styles — Bar Stock, Idlers, Ringfeder Connections, Torque Tamers, Custom Configurations, Special Hubs and more

- Materials — Aluminum, Steel, Ductile, Cast Iron, Phenolic, Stainless Steel or Plastics

- Finishes — Hard Coat, Food Grade, Zinc, Black Anodize, Nickel Plating, Custom Plating or any Special Coatings

- Processes — Hob Cutting, Shaper Cutting, Die Casting and Molding

- Services include sub-assembly, press bearings,

sprocket/bushing balancing and index marking.

- CAD drawings accepted.

- Quoting usually within 48 hours.

If you are unsure as to

what considerations need to be made for your non-standard metal component then the

Gates Metals Technical Guide is a great resource to help you further understand

the available options and their relevance to your specific needs. Of course our made-to-order metals team can

always be contacted at 800-709-6001 or MakeMyMetal@Gates.com to answer any questions and develop a quote for your metal drive components needs.

Tuesday, July 15, 2014

Abrasion Resistant Covers - Tough Covers That Extend MEGASYS Hose Life

Gates abrasion-resistant covers available on MegaSys hoses are tested and proven to stand up under the harshest operating conditions. These convers increase hose service life, lower maintenance and replacement costs, and eliminate the need for costly hose protectors such as spring guards and nylon sleeves.

MegaTuff Hose Cover

• Super-tough cover solves abrasion and wear problems

• 300 times the abrasion resistance of standard hose covers

• Tested to 1,000,000 cycles without failure

• Resistant to oil, ozone and UV rays

• Outperforms any other abrasion-resistant hose covers on the market today

XtraTuff Hose Cover

• Mid-range abrasion-resistant cover

• 25 times the abrasion resistance of standard hose covers

• Resistant to oil, ozone and UV rays

Pressure Drop

What Is Pressure Drop?

Friction is defined as the resistance an object encounters in moving over another; solids, liquids, and gases all exhibit friction in their motion. In hose and piping systems, the result of this friction is pressure drop and heat generation that may be accurately estimated with engineering models.

Why Does Pressure Drop Matter?

If there is excessive pressure drop in a system, pumps will have to work harder, use more energy, and the working fluid will increase in temperature. Depending on the source of the additional pressure loss, it could raise the whole system pressure, increase wear, and introduce potentially dangerous over-pressure conditions, render some tools or equipment functions inoperable because of inadequate operation pressure, or create damaging cavitation and loss of net positive suction head (NPSH).

What Affects Pressure Drop?

The factors which contribute to pressure loss may be broken down into two general categories: mechanical components and fluid properties. Mechanical components such as valves, flow meters, quick disconnects, adapters, couplings, tubing, hose, etc., all contribute to pressure loss. The amount of pressure loss in mechanical components is impacted by criteria such as cross-sectional area, internal surface roughness, length, bends, and geometric complexity. Fluid properties such as density, viscosity, heat capacity, and bulk modulus will also contribute to pressure loss. Fluid properties are impacted by temperature, pressure, contamination, and time. Fluid velocity has the most impact. Fluid velocity is a direct product of flow rate and cross-sectional area.

What Can Be Done to Reduce Pressure Drop?

• Check pressure drop when non-identical replacement parts or ongoing system problems are observed.

• Use straight adapters and bent-tube couplings whenever possible.

• Replace worn parts and old fluids.

• Lower the fluid velocity.

Thursday, July 10, 2014

Tri-Power PowerBand Belts Now in Stock

It's the best of both worlds! Premium ethylene rubber, notched, classical section V-belts with a PowerBand construction.

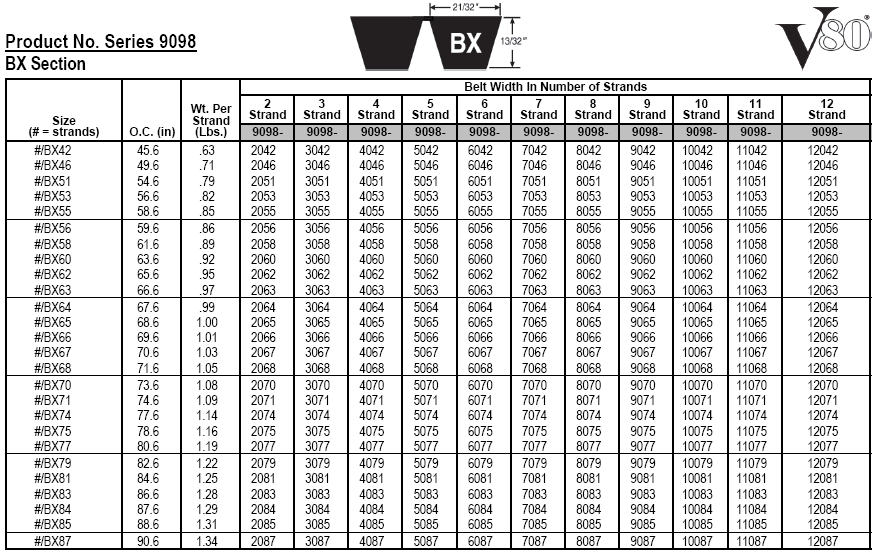

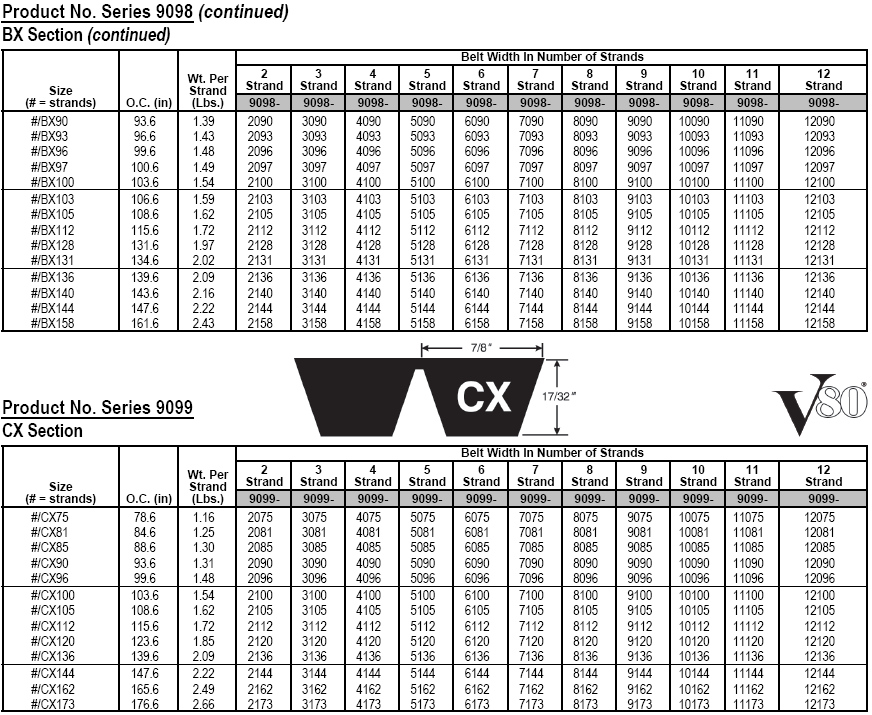

Standard/stock belt sizes are shown below. Click the images to zoom in. Custom sizes can be made to order (check with Product Application Engineering).

Standard/stock belt sizes are shown below. Click the images to zoom in. Custom sizes can be made to order (check with Product Application Engineering).

Tuesday, July 8, 2014

When Belts Fly: The Gates Nicolai MTB Team Elevates Carbon Drive to New Heights

You've probably heard it before, Gates belts are not allowed on anything that leaves the ground. No plane or UAV applications. Well, this application is just a little different, and while it is being demonstrated as leaving the ground, it doesn't quite qualify as a plane: When Belts Fly: the Gates Nicolai MTB Team Elevates Carbon Drive to New Heights

Subscribe to:

Posts (Atom)