Thursday, December 15, 2011

Interchanging Competitive Belts

If a belt replacement is not listed in the interchange, Gates Application Engineers may be able to assist using measured belt dimensions. The number of teeth (synchronous belts only), length, width, and thickness can help the engineers identify the closest standard replacement.

It should be noted that replacing belts based solely on measurements is not ideal. In these cases, Gates cannot guarantee that the materials would be the same or that the belt will provide the same performance level as the original belt.

Wednesday, December 14, 2011

Belt Drives and Oil Contamination

V-belt drives rely exclusively on friction to transmit power, so any contaminants that reduce friction also reduce the ability of the belt drive to transmit power. Banded type V-belts might have slightly improved resistance, compared to "raw edge" or "cut edge" type V-belts, with the outside cover temporarily shielding internal components. Also, neoprene based V-belts will have greater resistance to oil than EPDM based V-belts.

Synchronous belt drives rely less on friction to transmit power than V-belt drives. They also tend to perform better in oil contaminated environments. Rubber based synchronous belts, however, are still susceptible to swelling and adhesion system breakdown over time. While alternate rubber compounds may provide some marginal improvement in durability, it is best to prevent oil from contacting rubber synchronous belts if possible.

Gates Poly Chain type belts use a urethane based construction that is quite resistant to oil contamination. This prevents material swelling and breakdown that cannot be avoided with rubber materials. Note that synchronous belts still rely on friction to transmit power, so lubrications will interfere with power transmission. Poly Chain GT Carbon belts are used successfully in environments with heavy misting of oil based lubricants and cutting fluids, and have even been submerged in oil. Poly Chain GT Carbon belts are the best bet for applications that cannot avoid oil contamination.

Tuesday, November 8, 2011

Micro-V Belts

Thursday, November 3, 2011

Water & Synchronous Belt Resistance

With rubber synchronous belts, water soaking reduces the tensile strength of fiberglass tensile cords in addition to breaking down adhesion systems between the cord and the rubber compound. While aramid type tensile cords are more resistant to water than fiberglass, they are dimensionally unstable in the presence of water or humidity, so can result in belt length stability problems. Soaking also causes the rubber body to swell, lesser than but similar to oil contamination. This can negatively impact belt pitch fit with pulleys and sprockets in addition to material weakening. Additives to water such as lubricants, chlorine, anti-corrosives, etc. can intensify detrimental affects of water soaking.

Poly Chain GT Carbon belts are quite resistant to water soaking, and have even been used successfully in submerged applications. While urethane can exhibit a small amount of swelling, overall belt performance and the ability to transmit power remains relatively stable.

When considering the use of synchronous belt drive systems in moist or wet environments, the resistance of the hardware to corrosion is also very important. Coatings or treatments used on standard iron based hardware may not have adequate corrosion resistance. Special corrosion resistant coatings such as zinc or nickel plating are available on a made-to-order basis.

Contact our Made-To-Order Metals Group at (800) 709-6001 for further information about hardware corrosion protection options. Contact our Product Application Engineering Group at (303) 744-5800 for further information about applying belt drive systems in adverse environments.

Tuesday, October 25, 2011

Motorcycle Belts

Various aftermarket distributors also service the market, and they serve as an alternate source for replacement belts. However, some motorcycle belts sold through the original dealer network may be manufactured with proprietary constructions not available through aftermarket distributors.

The standard Poly Chain® GT® Carbon™ belts sold by Gates general market distributors have the GT tooth style. These belt are not recommended for use with motorcycle sprockets, which are typically designed with the HTD® tooth style.

Aftermarket distributor can typically assist with custom motorcycle applications. However, belts in lengths other than those available from aftermarket distributors may require new tooling at costs in excess of $25K per mold.

Monday, October 17, 2011

Synchronous Belt Drive - Test for Structural Integrity

Since synchronous belts will not act as a clutch, it is important to make sure that the drive structure is adequate. This is more of a concern for HVAC type applications, given their structural considerations.

To check for structural rigidy, first make sure that the system is powered off, locked down and tagged out. Never touch or work with any belt system without taking appropriate safety measures.

Then, grab the opposing belt spans and push or squeeze them towards each other. While doing this, keep an eye on the shafts in the system. If you see significant movement or deflection, the system is not an ideal candidate for synchronous belt conversion without further structural strengthening. If you do not see any movement, or minimal movement, the system's structure is adequate and a good candidate for converting to synchronous belts.

Tuesday, October 4, 2011

Rust Inhibitor - Krown KL 73

Thursday, September 29, 2011

Belt Installation and Maintenance Toolbox

Tuesday, September 13, 2011

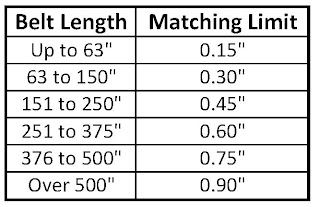

V-belt Matching

Many Gates V-belts are manufactured within the above match tolerances, allowing stocked belts to run as matched sets. However, there are some exceptions to the match tolerances listed above. V-belts with aramid tensile cords stretch very little, requiring a match tolerance that is tighter than the RMA standard. V-belts with aramid cords (such are Predator®) should be matched by selecting belts with a single punch code.

Many Gates V-belts are manufactured within the above match tolerances, allowing stocked belts to run as matched sets. However, there are some exceptions to the match tolerances listed above. V-belts with aramid tensile cords stretch very little, requiring a match tolerance that is tighter than the RMA standard. V-belts with aramid cords (such are Predator®) should be matched by selecting belts with a single punch code.Monday, August 22, 2011

Bushings and Keys

Tuesday, August 2, 2011

Sonic Tension Meter Accessories

- a cord sensor (7420-0206)

- a storage case

- batteries

- a manual

- a mass constant quick reference card

Thursday, July 21, 2011

Considerations for Synchronous Belt Drives on HVAC Applications

Designers that are considering using synchronous belts on HVAC drives need to be aware of this potentially high start up load.

If a soft start or variable frequency drive (VFD) is used on the drive, there is no need to take any special design precautions as the load is ramped up gradually.

If an across the line start up happens infrequently, simply applying a bit more installation tension will help prevent any ratcheting or start up issues.

If start ups occur regularly and/or frequently, it is good practice to add .2 to the service factor when designing the synchronous belt drive. This will provide a slightly more conservative drive design that will avoid any issues at start up. Learn more about HVAC drives and synchronous belts at Gates.com.

Friday, July 15, 2011

Taper Lock Bushings

Tuesday, July 5, 2011

Synchronous Belts & Exposure To Water

Prolonged contact with water also causes rubber compounds to swell, although less than with oil contact. Internal belt adhesion systems are also gradually broken down with the presence of water. Additives to water such as lubricants, chlorine, anti-corrosives, etc. can have a greater detrimental effect on belts than pure water.

Poly Chain GT Carbon belts use polyurethane compound and carbon fiber tensile materials that are both very resistant to water. Poly Chain GT Carbon belts can withstand prolonged contact with water without detrimental effect.

Sprockets operating in the presence of water may be vulnerable to rust and corrosion unless resistant materials or coatings are used. Sprocket corrosion can result in accelerated belt wear and tension loss. These can both shorten belt life significantly. For assistance in the design and acquisition of rust and corrosion resistant sprockets and bushings, contact Gates Made-To-Order Metal team.

Tuesday, June 21, 2011

Gates Drive Design Manuals

There are several manuals available at www.gates.com/drivedesign/:

- Poly Chain® GT® Carbon

- PowerGrip® GT2®

- Heavy Duty V-Belt

- HVAC

- Light Power and Precision

- Air-Cooled Heat Exchanger

- Drive selection procedures (including power rating tables)

- Gates hardware specifications (for standard sheaves, sprockets, bushings, etc).

- Discussion of design considerations such as installation tension, conductivity, alignment, noise, flywheel effect, NEMA motors, tolerances, idlers, etc.

- Standard calculations

- General troubleshooting guidelines

Tuesday, May 31, 2011

Splicing and Clamping Synchronous Belts

Clamps are often used to attach two ends of a synchronous belt together. If this is done, the clamp must be contained on the belt span between the two pulleys. If a clamp ever attempts to ride over a pulley, catastrophic results will surely follow. If a clamp is used to attach two ends of a synchronous belt, a minimum of 6 teeth in mesh on each side of the belt is recommended. Anything below 6 teeth will lower the belts available working strength (6 teeth = tensile strength of belt), and premature belt failure from tooth shear is more likely to occur.

Tuesday, May 24, 2011

Synchronous Belt Storage

Whenever possible, store your belts in the original packaging until the moment it is ready for installation. This is the best way to keep from damaging the tensile cords of the belt.

Keep the belts away from direct sunlight and moisture. One way to avoid this is by keeping your belts away from windows.

Keep the belts out of the heat. Do not store your belts near heaters or radiators. Make sure that they are not in the airflow of a heating device.

Don’t store belts on the floor. This may seem a little over the top, but floors are high traffic areas, and a belt could easily be stepped on or rolled over, causing tensile cord damage.

Keep the belts away from chemical exposure. Any place that has solvents in the air could damage your belts. This includes chemicals such as ozone, which could be present near transformers or electric motors.

Belts should ideally be stored in a cool dry environment at a temperature of 85 degrees F or less with lower than 70% relative humidity. If done properly, a belt can be stored for up to 6 years.

Tuesday, May 17, 2011

Synchronous Drives Operating in Environments with Dust and Debris

Debris should be prevented from falling into any synchronous belt drives by using screens or guards. Debris caught in belt drives is generally either forced through the belt or may result in a stalling of the system. In either case, serious damage will occur to the belt and related drive hardware.

Monday, May 9, 2011

Gates Flat Idler Pulleys

The flat idler pulleys can be used with the existing idler brackets and they are available in a range of sizes for use on both synchronous and V-belt drives. Available sizes and technical details regarding Gates idler product line are available at www.gates.com/idlers/.

Wednesday, May 4, 2011

Custom Synchronous Belt Sizes

Making stock belts in custom widths is usually easy to do. Synchronous belts are made on a mold that makes a single wide belt which is then cut down into the individual belt widths. If you need something other than a standard width, we require that you purchase the slabs worth of the custom width because we must set the tooling up to cut the whole slab. The number of belts will depend on the mold size and the width you are requesting.

Making custom lengths is much more difficult. Each size length is made on its own individual mold. In order to do a custom length not listed in our catalog, we have to machine a new mold for that size. This means that you will be charged for tooling fees and minimum order quantities, which is usually not feasible except for equipment manufacturers that will be placing large orders.

Tuesday, April 26, 2011

Polyflex Belts Unique Characteristics

Liquids act as lubricants – Because of the broad 60° groove angle, belt wedging forces are reduced making the coefficient of friction between belts and sheave grooves critical in transmitting load. Liquid contaminants such as water, chemicals or oils can decrease the coefficient of friction, allowing belt slip. Belt slip can result in belts turning over in the sheave grooves. Heat from belt slippage may also cause belt softening or melting, resulting in catastrophic failure. Adequate shielding should be used when liquid contaminants (either airborne or splashed) are present near Polyflex drive systems.

Damage from debris – The 60° belt sidewall angle and thin cross section both make these belts susceptible to debris. Debris can cause belt instability resulting in belt turn-over, which will result in catastrophic failure. Adequate shielding should be used when debris is present near Polyflex drive systems.

Backside idlers – Polyflex belts running on flat backside idlers can create objectionable noise due to the molded ribs on the back of the belts. Perceived sound level is inversely proportional to the sheave diameter, so using larger idlers can reduce generated noise.

Static conductivity - Polyflex V-belts do not meet the RMA requirements for belt conductivity. Polyflex V-belts should not be used in potentially explosive or flammable environments without the use of adequate static dissipating devices such as grounding brushes.

Friday, April 15, 2011

Measuring A Synchronous Belt

Length: measure the outer circumference of the belt. If the belt is broken in half, just measure the total length.

Width: measure the width across the back of the belt. This could be in metric or imperial units; it doesn’t matter which one you give us, we just need the best measurement you can get.

Pitch: measure from the center of one tooth to the center of the next tooth. Simple, but sometimes the teeth are small. Getting as close as possible on this really helps – see above about the metric/imperial units issue.

We will also ask you to count the teeth, it’s not that we don’t trust your measurements, but this is verification of the correct length and pitch measurements. I know, I know… There may seem to be a lot of them, but even a belt with 200 teeth will only take a minute or two to count.

That’s it, from here, all it takes is knowledge of our product line to ID the type of belt, and a catalog to see if it’s a stock size. Sometimes we can’t cross a belt because it was made special for someone. In these cases you will have to go back to the manufacturer of the machine that your belt came on – even if we made the belt in the first place.

Tuesday, April 5, 2011

Fan Drives: High Start Up Loads and Synchronous Belt Drives

Start up loads can be a significant concern when evaluating potential drives for conversion to PowerGrip® GT®2 or Poly Chain® GT® Carbon belt drives. PowerGrip® GT®2 and Poly Chain® GT®Carbon belt drives will transmit all of the start up torque, where V-belts may slip if the load is excessive. Due to the inertia of the fan, start up loads can potentially be 150% to 200% of the normal operating load. This is obviously much more of a concern when the drive will be operating on a system that frequently cycles on and off. Drives that run continuously will only see the start up load intermittently, so are not as sensitive to the combination of high start up loads and weak structures. It is important that the start up load be considered when evaluating a drive. If the structure is weak, a high start up load will further adversely effect the PowerGrip® GT®2 or Poly Chain® GT® Carbon belt drive's performance by allowing center distance collapse. This reduction in center distance results in an under tensioned belt which may wear prematurely from being undertensioned, or even worse, premature failure from ratcheting. If an electrician or properly trained technician is available, an ammeter can be used to compare the start up amperage to the steady operation amperage. If the amperage is 1 1/2 to 2 times the steady state amperage, the structure should be carefully inspected to insure that it is robust enough to prevent center distance collapse upon start up. With the drive shut off and safely locked out, the structural rigidity can be checked by pushing the two belt spans inward toward each other and looking for any relative movement in the structure.

Tuesday, March 29, 2011

Belt Drive Inspection and Replacement

Tuesday, March 22, 2011

Selecting the Right Synchronous Replacement Belt

However, the variety of styles available from numerous manufactures increases the difficulty of identifying a replacement belt. To help users select the proper replacement belt, Gates has created the Gates Belt/Sprocket Interchange (http://www.gates.com/index.cfm?location_id=3881). At this site, users can select their sprocket type and determine the best Gates replacement belt.

Friday, March 4, 2011

Rim Speeds and Maximum Diameters

Thursday, February 24, 2011

Belt Drives and Environmental Temperature

In general, the maximum recommended temperature for belt drive systems for standard belts is 185 deg. F (85 deg. C). For rubber belts, temperatures exceeding this can result in gradual compound hardening and eventual cracking as belts stiffen. For urethane belts such as Poly Chain GT Carbon, the urethane will may begin to soften and will eventually melt at temperatures exceeding 200 deg. F (93 deg. C). There are a few options for belt drives operating in high temperature applications, but belts made from materials with higher temperature resistance are still limited to a maximum temperature of about 230 deg. F (110 deg. C).

Belts can "overheat" from slippage even when environmental temperatures are not excessively hot. If belts are hard and appear glazed from heat, always check to make sure the tension is at the recommended level, and that sheave grooves are not worn excessively. In most normal environments, belt surface temperatures do not typically exceed 120 deg. F (49 deg. C) or so.

Belts are generally limited to a minimum temperature of about -30 deg. F (-34 deg. C). Rubber belts operating in temperatures lower than this can harden and crack. Cold soaked belt drive starts are especially vulnerable to belt cracking. Poly Chain GT Carbon belts are capable of operating at temperatures down to -65 deg. F (-54 deg. C).

Monday, February 14, 2011

Gates Launches New Metals Technical Guide

- Material considerations

- Manufacturing and process capability

- Bushing capability

- Sheave specifications

- Sprocket specifications

- Gates Made-to-Order Metals team

The guide is available for download at www.gates.com/catalogs/ under the Power Transmission Catalog Collection link.

Wednesday, February 9, 2011

Designing Replacements for Existing Drives

While we can calculate the power ratings for the old drive, if we design the new drive based on the old drives ratings we are trusting that it was designed properly in the first place. However, it is entirely possible that the old drive was improperly sized because the customer is replacing it for a reason! By knowing the horsepower and rpm of the motor, as well as the components of the old drive we can follow our proven design procedure to give the best results to the customer.

To design a belt drive we need to know:

-Horsepower and rpm of the motor

-Ratio of any gearbox in between the motor and belt drive if applicable

-Desired speed ratio for the belt drive (The old pulley sizes can tell us this)

-Center distance (The pulleys and belt length can tell us this)

-Shaft diameters

-A description of the operating conditions (24/7/365 or high shock loads?)

Thursday, February 3, 2011

Synchronous Belt Meshing Frequency

Meshing frequency can be calculated as follows:

(# Sprocket Grooves x rpm) / 60 = cycles/sec

Friday, January 21, 2011

Minimum Diameters

Tuesday, January 11, 2011

Belt Drives and Dissipating Static Charge Buildup

In order to minimize possible issues with static charge build up, V-belts are generally manufactured in conductive constructions (Predator and PowerRated belts are not static conductive), and rubber synchronous belts can be produced in conductive constructions on a made-to-order basis. Note that Poly Chain GT Carbon belts cannot be produced in a conductive construction. The Association for Rubber Products Manufacturers (ARPM; formerly Rubber Manufacturers Association) defines standards for static conductive belts in their bulletin IP-3-3.

Static conductive belts meeting the ARPM Standard IP-3-3 should have sufficient conductivity to prevent measurable static charge buildup, thus preventing static discharges. Belt drive systems operating in potentially hazardous environments, though, must be properly grounded. A continuous conductive path from belt to ground is necessary to bleed off static charges. This path includes a static conductive belt, a conductive sprocket, a conductive bushing, a conductive shaft, and conductive bearings, all along the path to ground.

In hazardous environments, additional protection should be employed to assure that there are no accidental static spark discharges. Unusual or excessive debris or contaminant on belt contact surfaces or sprocket grooves, for example, can reduce the ability of belts to conduct static charges into hardware. In addition, belt conductivity properties are known to decline over time from normal use. Static conductive brushes or similar devices should be employed to bleed off any residual static buildup that might remain around belts.

Tuesday, January 4, 2011

Power and Fan Speed for Belt Drive Conversions

Initial_Horsepower/New_Horsepower = (Initial_Fan_RPM/New_Fan_RPM)^3

A small speed change can result in a substantial increase in power consumption. Therefore, this relationship should be considered when replacing a V-belt drive with a synchronous belt drive for energy savings.

To ensure that the fan speed does not increase, the design speed ratio should be based on a measured fan shaft RPM of the existing V-belt drive. This measurement can be made with a contact or a strobe tachometer.