Tuesday, February 16, 2016

Which Sprockets Have Flanges?

If you've read the blog post on flanged sprockets then you're aware that not all sprockets have flanges. Most applications only need flanges on one sprocket. For this reason larger sprockets don't have flanges. The table below shows the number of grooves in the largest standard sprocket with flanges. Any standard sprocket with more teeth will not have flanges.

Sprocket details may change without notification.

Wednesday, February 3, 2016

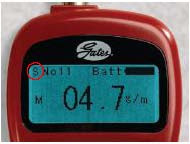

Easy Fixes For Obtaining Readings From Gates 508C Sonic Tension Meter

The new Gates 508C Sonic Tension Meter is an excellent tool,

and is very easy to use. Occasional user

difficulties often result from some common issues. Solutions to a couple of common issues

follow.

If readings can’t be obtained, first check to see that the

meter is set in the standard frequency mode.

Look for an “S” in the upper left hand corner of the screen. If an "H" is displayed instead, the meter is

set in the high frequency mode (500 hz to 5000 hz) and normal belt span

frequencies cannot be detected.

If readings can’t be obtained, first check to see that the

meter is set in the standard frequency mode.

Look for an “S” in the upper left hand corner of the screen. If an "H" is displayed instead, the meter is

set in the high frequency mode (500 hz to 5000 hz) and normal belt span

frequencies cannot be detected. Change the frequency mode by holding the “Range” key down (zero button) until the screen changes. Then toggle to select the “Standard” range with the “up” (8 button) and “down” (2 button) keys. Press “Measure” afterward to return to the main screen and look for the “S” in the upper left hand corner of the screen.

When using the meter to measure belt tension in terms of

lb., kg. or N, “Mass”, “Width” and “Span” constants need to be entered. These constants are available in the tensioning

section of drive design reports from our Design Flexibility software. Correct constants are necessary to obtain

correct belt tension readings.

When using the meter to measure belt tension in terms of

lb., kg. or N, “Mass”, “Width” and “Span” constants need to be entered. These constants are available in the tensioning

section of drive design reports from our Design Flexibility software. Correct constants are necessary to obtain

correct belt tension readings.

Many users prefer the simplicity of span frequency, but don’t

know whether the “Mass”, “Width” and “Span” constants need to be entered. The constants do not effect belt span

frequency measurements, but incorrect constants can result in a meter display

overflow, or “Error Re-Measure” message.

If the meter is to be used to measure belt span frequencies

only, here’s a really handy trick. Enter

values of 1.0 for all three constants. Now

the meter will display zero tension, but press the “Hz” button for the

frequency display mode. Now the meter

will display accurate belt span frequency values, not display belt tension, and

not display an error message from incorrect constants.

Contact Product Application Engineering at 303-744-5800 or at ptpasupport@gates.com for further assistance with Gates Sonic Tension Meters.